Product Gallery

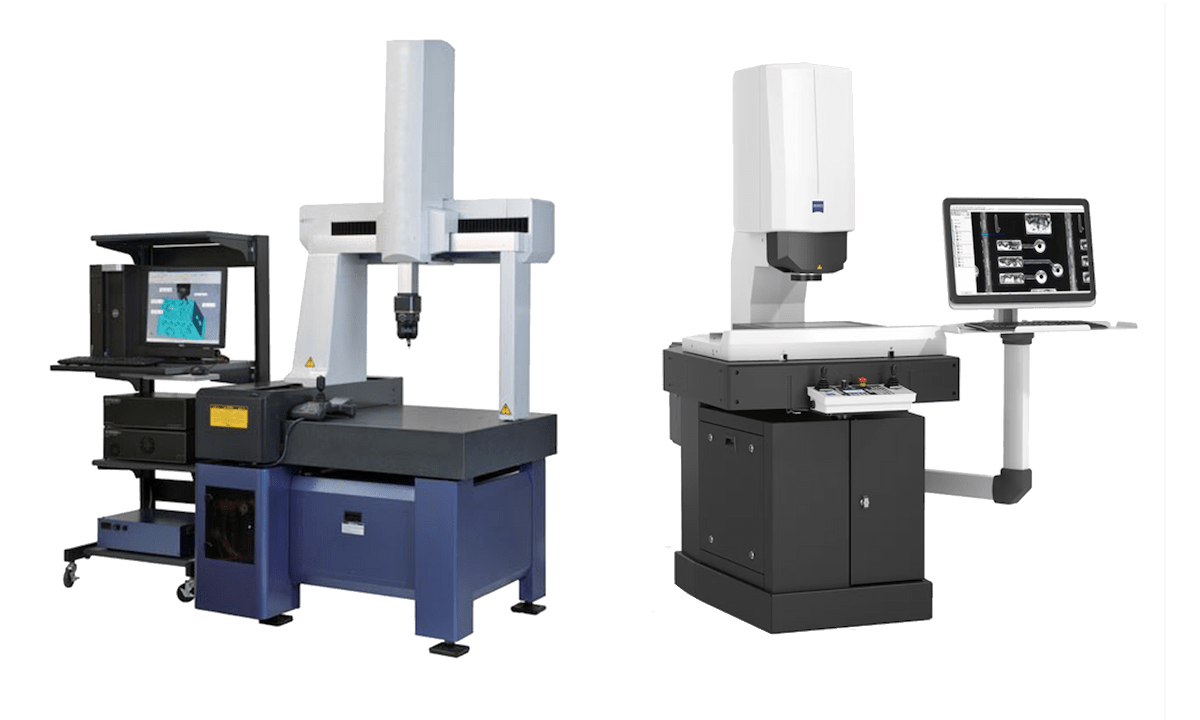

Automation

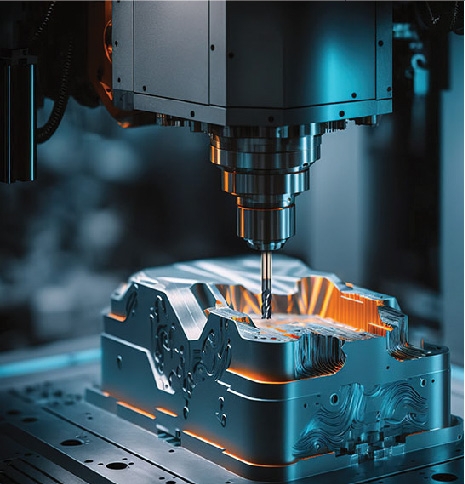

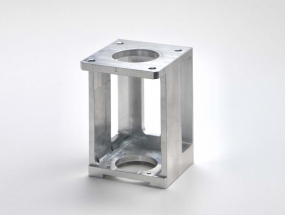

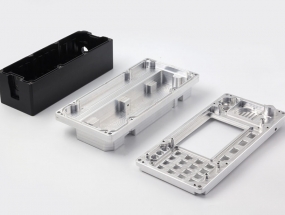

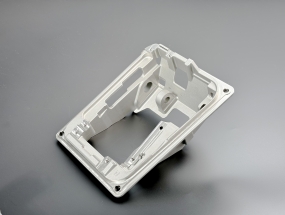

Machine Part

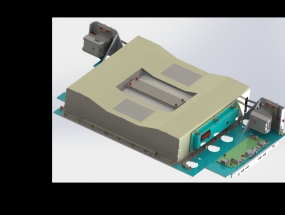

Semiconductor

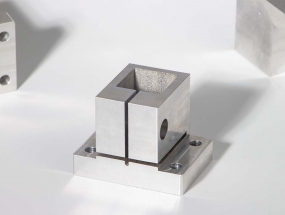

Mold Components

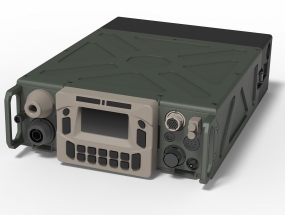

Telecom

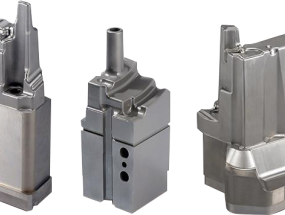

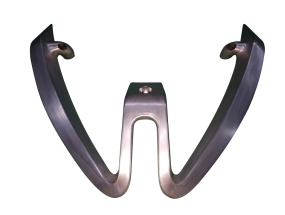

Automotive

Medical device

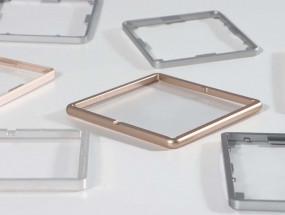

Consumer Device

Other